This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Numerical simulation in response to current energy issues and challenges

Civil nuclear power, using calculation codes such as RCC-M and our M-fem App

The civil nuclear industry remains an important source of electricity production in the European Union (around 22.1% of total production in 2022 according to the European Commission). Permanent Representation of France to the European Union with an installed capacity of almost 1,024 GW, compared with 38.5% for renewable energies and 39.4% for fossil-fired).

In Switzerland, according to the SwissFederal Office of Energy, nuclear power will account for around 19% of electricity production in 2021, with an installed capacity of almost 3 GW, compared with 68% for hydroelectric power, 11% for solar power and 2% for fossil-fired power. In France, it will account for around 67% of total production in 2020, according to RTE, with an installed capacity of almost 61 GW, compared with 13% for hydroelectric dams, 8% for wind power, 7.5% for fossil-fired, 2.5% for solar and 2% for biomass.) Its low impact in terms of greenhouse gas emissions (such as CO2) is currently one of its main advantages over fossil fuels.

The question of civil nuclear power, in particular the safety and security of nuclear power plants and the management and storage of nuclear waste resulting from uranium fission, is always at the heart of debates. The industry, via theAFCEN among others, publishes very strict construction and calculation codes such as :

- RCC-M – Rules for the design and construction of mechanical equipment for PWR (Pressurized Water Reactor) nuclear reactors,

- RCC-MRx – Rules for the design and construction of mechanical equipment for high-temperature, experimental and fusion nuclear facilities.

- Other equivalent rules, such as ASME III, published and adopted in the USA and many other countries

The use of these codes (known as “dimensioning codes”) facilitates the chain from design to commissioning and operation of mechanical systems (but also civil engineering or control and energy systems) that links designers, architects, manufacturers and operators of such systems, as well as the acceptance of justification dossiers with the safety authorities that authorize such installations (nuclear safety authority, etc.). ASN -for France- or the Federal Nuclear Safety Inspectorate IFSN -for Switzerland).

Pascal SABBAGH, co-founder of DAES, is one of the experts invited to join the RCC-MRx working group, whose aim is to enrich and improve existing rules.

The simulation technologies in which DAES has expertise have the dual advantage of meeting the safety and standards concerns of the nuclear industry, while optimizing your design projects. DAES helps you to rationalize your human and material resources in line with current standards, using ANSYS, M-fem and MRx-fem applications.

In the civil nuclear sector, DAES is involved in projects related to the following activities

- construction and operation of nuclear power plants

- Analysis of fluid and gas transport systems

- Pipe creep and burst analysis

- Accident simulation, pumps and valves, storage tanks

- radioactive waste management and nuclear waste burial ;

- Spent fuel cask design

- welding and analysis of residual thermal stresses, nuclear waste tanks, etc.

Fusion and the ITER project, but not only...

DAES is also working with renowned international partners to develop ambitious R&D projects across a broad spectrum of nuclear technologies, including fusion.

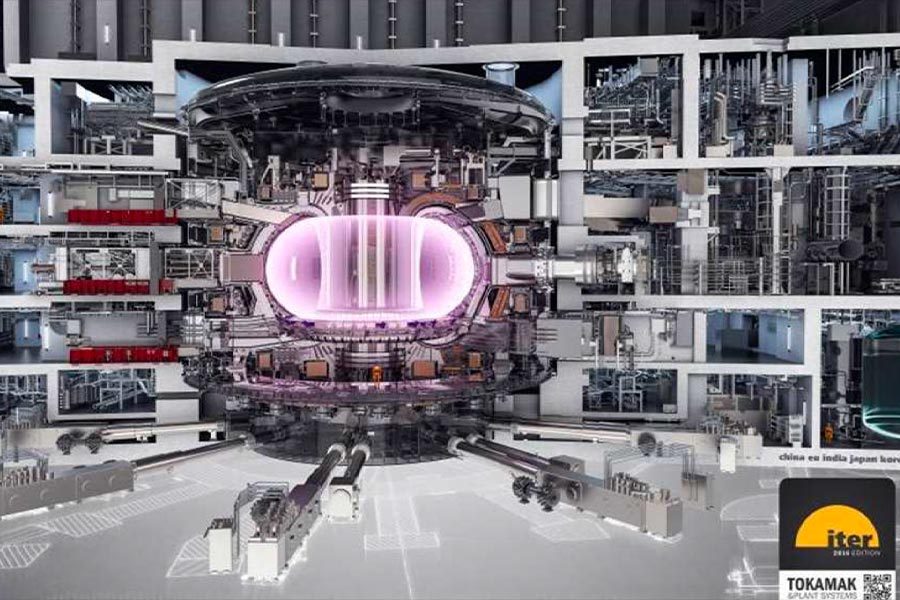

DAES has been contributing to the ITER project for over 5 years. It has expertise in the development of mechanical systems specific to a Tokamak such as the one under construction at the ITER site. The aim of ITER is to demonstrate that it is possible to convert the energy of the stars (thermonuclear fusion energy as it occurs within the stars, including our Sun) for the benefit of mankind, to produce a renewable, sustainable and inexhaustible source of energy to replace fossil fuels and thus limit global warming. The aim of ITER is to extract the energy from this fusion (hydrogen isotopes producing helium) which, once the process has been industrialized, will be used to produce heat and electricity.

DAES supports the design and dimensioning of such systems.

In the Tokamak building

The “first wall blankets” modules that form the tokamak’s internal “skin”. They have to withstand high stresses of various types (thermal stresses due to plasma and neutron radiation, electromagnetic and seismic stresses): At DAES, we are particularly involved in CFD, thermal, structural and electromagnetic analyses (according to RCC-MR, RCC-MRx, ASME III and ASME VIII rules).

DAES also supports private efforts towards commercial fusion, and is actively involved with private players developing these technologies, enabling them to benefit from its experience gained on ITER.

Gas pedal technologies - Isotope production targets - Neutron production targets - Spallation targets

The founders of DAES have been involved in a number of projects at CERN, starting with the famous LHC, with contributions on objects interacting with the proton beam, and going on to the Laguna LBNO (Long Baseline Neutrino Oscillations), an underground neutrino observatory to study neutrino oscillations over long distances, investigate the Grand Unification of elementary forces and detect neutrinos from astrophysical sources.

On the various projects, the DAES founders brought their expertise to bear on :

- Thermo-mechanical simulation,

- Thermal simulation

- Simulation and dynamic analysis

- Designing beam dumps

- Design of high-power targets (EURISOL, ESS, etc.)

- Design of radioisotope production targets.

-

- The design of the rotating “target” wheel

- Definition of the overall architecture of the building containing the target

- Proton beam window design

- Defining the safety control system

DAES is the leader of the VULCAN project (Versatile Ultra-Compact Accelerator-based Neutron source) EUREKA-EUROSTARS E! 115722 with its partners DTI and Xnovo: VULCAN is a compact, “turnkey” pulsed neutron source, affordable and usable by research and technology organizations, industry and universities, in particular for training scientists in neutron techniques.

VULCAN’s applications include measuring the internal properties of metal and ceramic structures after any manufacturing process, including additive manufacturing, and measuring the evolution of metal anodes (deposition/stripping, dendritic growth) in Li-ion (or Li-polymer) batteries and fuel cells.

DAES is in charge of :

- Project management and systems engineering

- Defining the machine architecture right down to the neutron guide

- Target-moderator-reflector design

Validation tests of the Target-moderator-receiver assembly will be carried out at CERN’s gas pedal complex in 2023.