Dynamic analysis

Dynamic simulation: an alternative and complement to physical testing

The use of dynamic simulation is an interesting complement or alternative to physical testing in many cases: exceptional or even unique products or components, complex or even impossible physical tests, difficulty in sourcing materials… these are just some of the reasons why our customers turn to this type of simulation. Our assets include

Key factors in the success of the simulation are a good definition of the expected level of accuracy and a good understanding of the system physics.

Correlation with physical tests enables full validation of the model.

Dynamic analyses can be of several kinds:

- Implicit or explicit transient analysis (fast dynamics). These simulations can consist of rigid bodies only (multi-body analysis).

- Vibration analysis (modal, spectral, PSD)

- Harmonic analysis

Implicit transient analysis is a modeling technique that simulates the behavior of a system over time by iteration. It can be used to model the behavior of a system at different levels of detail, taking into account the interactions between different parts of the system. Dynamic simulation can be used to study the behavior of complex systems, such as mechanical, electrical, hydraulic or thermal systems.

Fast dynamic simulation, on the other hand, is a simulation technique that enables dynamic systems to be simulated with very fine time resolution. It uses faster numerical methods than conventional dynamic simulation to solve the model equations, enabling high-frequency simulations. This technique is often used to study the behavior of systems subjected to rapid changes, such as shocks, explosions, etc…

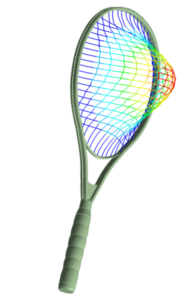

Linear vibration analyses are based on a modal analysis of the system. By processing and combining these modes, a time-independent response corresponding to the applied frequency spectrum can be obtained.

Harmonic analysis provides the system response for a given frequency under alternating loads. While modal analysis enables us to define resonance frequencies, harmonic analysis enables us to calculate their response (displacements, stresses) at and around these frequencies.

Simulation provides invaluable answers to questions about impact, materials and safety.

In many innovation projects, simulations are used to test behavior under different conditions in order to meet specified criteria. Here are some project examples:

They can be based on existing test methods such as the sheep pendulum test, the development of specific tests according to standards (e.g. NIHS 91-10 watchmaking standard) or mechanical criteria. In addition to test modeling, we can mention drop calculations (e.g. a drill falling to the ground), which require the definition of the critical drop angle prior to the calculation.

Depending on the analyses selected, the software solutions used at DAES will mainly be :

- Abaqus, LS-DYNA: finite element calculations, impacts and shocks on all types of materials (viscoelastic, composites, plastics….), taking thermal and fluidic phenomena into account where necessary.

- OpenModelica: 1-dimensional electrical, mechanical and thermal control systems, OpenSource counterpart to tools such as Simulink or Dymola

- Ansys Mechanical for implicit dynamic, vibratory and harmonic analysis.

- Ansys Mechanical for rigid body dynamics simulations (similar to MSC Adams) for, for example, vehicle suspensions, braking systems, lifting mechanisms, etc.