This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

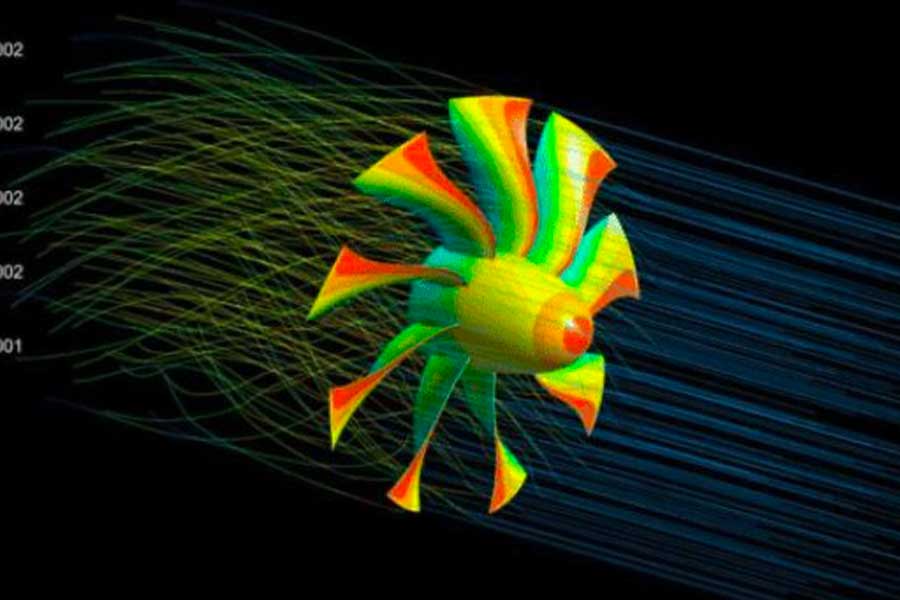

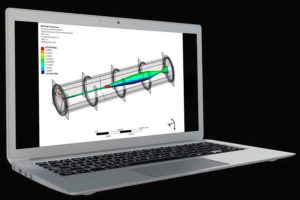

PROCEDES-1D simulation

The added value of 1D process simulation

Beyond these fundamental principles, the spectrum of applications for 1D-process simulation is vast. DAES, for example, has cultivated expertise in a wide range of fields, from thermodynamic circuits such as gas-fired power plants, to multi-body simulations in mechanics. It is also involved in chemical and reactive processes, vehicle traffic and much more.

In short, in an era when engineering is continually striving to improve precision and efficiency, 1D-process simulation is an invaluable tool, striking a balance between overview and detailed analysis.

The added value of 1D process simulation

The world of engineering is littered with complexities, where the slightest variation can have major repercussions on the overall system. To navigate this sea of uncertainty with ease, 1D-process simulation is an indispensable compass, offering both a panoramic view and the finest detail. DAES, through its specialization, perfectly illustrates the versatility and usefulness of this simulation method.