This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

MA-VL and HA waste from irradiated fuel in nuclear power plants

- July 9, 2020

- Articles

One of the major challenges facingnuclear energy is the management and storage of high-level, long-lived nuclear waste. They remain dangerously radioactive for hundreds of thousands of years (generally 200,000 years) and require special treatment, regulated by the states that guarantee public safety. In France, nuclear waste is managed by ANDRA . It is classified according to two main characteristics: its hazardousness and its lifespan. These characteristics are broken down into six waste categories. In this article, we focus on the following two categories:

- Long-lived intermediate-level waste (ILW)

- high-level waste

Most of the LV-AM comes from nuclear fuel support structures, e.g. zircaloy fuel assembly cladding. The waste is compacted to reduce its volume, then packaged in metal or concrete containers. They represent 3% by volume of all nuclear waste produced in France.

HA comes from spent fuel processing. These are non-reusable residues such as actinides or fission products. They are charred and then vitrified. The glass-waste mixture (3% waste, 97% glass, by mass) is packaged in stainless steel packages, which are sometimes placed in a second steel container. This HA waste represents 0.2% by volume of all nuclear waste produced in France. They concentrate 96% of radioactivity.

These two categories of waste(MA-VL and HA) represent a small portion of the total mass or volume of nuclear waste. However, they have periods of several hundred thousand years, and are highly toxic. They are all derived from spent fuel. One solution under study is deep reversible storage.

MA-VL and HA waste management

The management of this waste is divided into two phases:- Storage: Temporary, based on the principle of continuous thermal evacuation to cool irradiated fuel.

- Storage: This is definitive and is based on the principle of decreasing levels of radioactivity in irradiated fuel.

Temporary storage of radioactive waste

We distinguish two categories of temporary storage systems: pool and dry.Pool storage

-

PRINCIPLE

-

STORAGE POOL

-

THERMAL INERTIA AND RADIATION SHIELDING

Dry storage (not used in France)

-

PRINCIPLE

-

STORAGE STRUCTURE

-

RADIATION SHIELDING

-

LIMIT

Storage

-

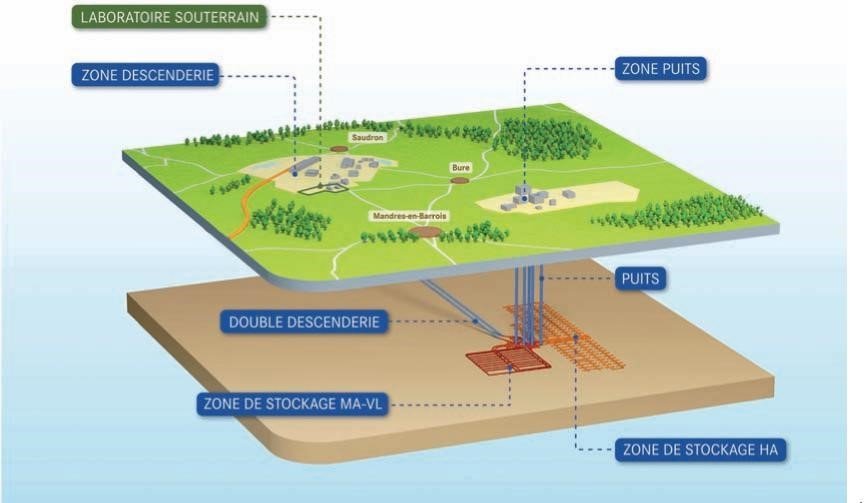

GEOLOGICAL REPOSITORIES

The containment and isolation of waste is ensured by various elements:

- the container into which the waste is introduced before being placed in the final storage cell.

- in some cases, the overpack: an additional sealed package that transforms primary vitrified waste packages into storage or disposal packages.

- the natural barrier provided by the receiving rock.

-

PRINCIPLE OF FINAL STORAGE

The defining characteristic of final disposal, as opposed to interim storage, is that the objective of waste recovery is not systematic. In other words, the waste disposal facility is closed and sealed, without the need for an additional above-ground operating facility.

-

WASTE RECOVERY IN QUESTION

In any case, it is always possible to keep the storage facility and its environment under surveillance for as long as deemed necessary. The plant can be designed so that stored waste can be recovered in the future. ANDRA envisages reversibility of the deep disposal facility for a period of 100 years.

-

LIMITS

Deep geological disposal requires safety demonstrations concerning :

- The ageing of buried waste packages over several thousand years. The aim is to prove that the rock will retain radioactive species once corrosion has damaged the packaging.

- Resistance to geological events such as earthquakes.

- The memory of the landfill site. Remembering where waste is located is a key issue. This means transmitting information to many generations of individuals. It is therefore necessary to devise a means of communication that lasts beyond the language, and a communication medium that does not alter.

The different stages of radioactive waste disposal in video I The Cigéo project

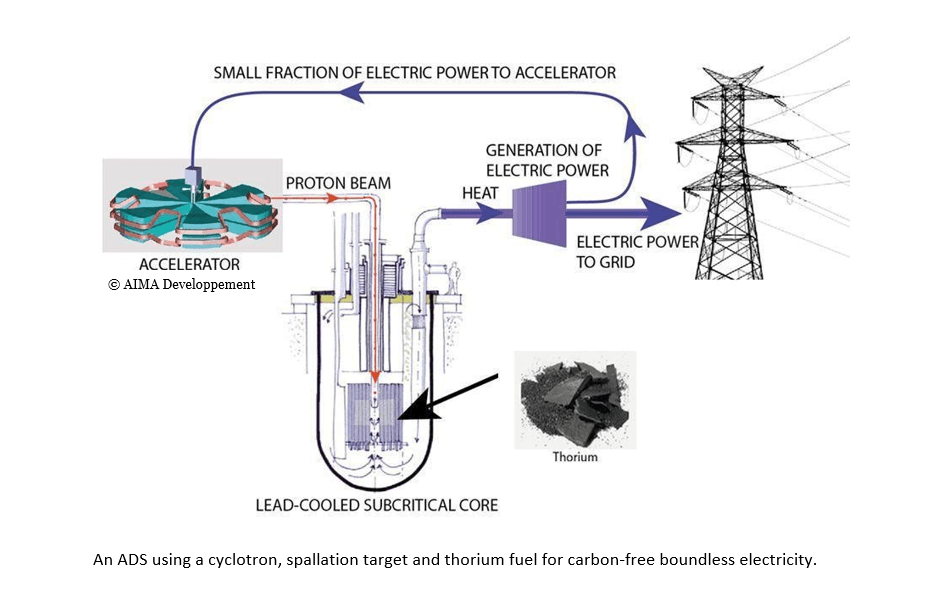

INNOVATIVE PROCESSING SOLUTIONS FOR MA-VL AND HA

-

A LOW-CARBON FUTURE

-

DAES EXPERTISE :

- Structural analysis

- Non-linear and contact modeling

- Impact and explosion

- Design optimization, noise and vibration, fatigue

- Motion and system analysis

- Stress and strain analysis

- Thermal analysis and heat transfer

- Acoustics

-

A RESPONSIBLE AND INNOVATIVE PARTNERSHIP

-

TRANSMUTATION AND RADIOTOXICITY

-

WNE 2020 – For a Low Carbon Society

-

We’ll be taking part in the WNE 2020 trade show in the near future, to take part in the current and future challenges facing the nuclear industry, and to present a promising project alongside the Transmutex teams.

To keep up to date with our news and other DAES events, follow our Blog and Linkedin Page.

For more information about our solutions, please contact us.